Moisture Control Management

at Weïss Advanced manufacturing, llc

Why Moisture Matters

Moisture is one of the leading causes of product damage in industrial abrasives,

overlay papers, and decorative surfaces. Even trace amounts can cause:

• Caking and clumping in aluminum oxide and other fine abrasives

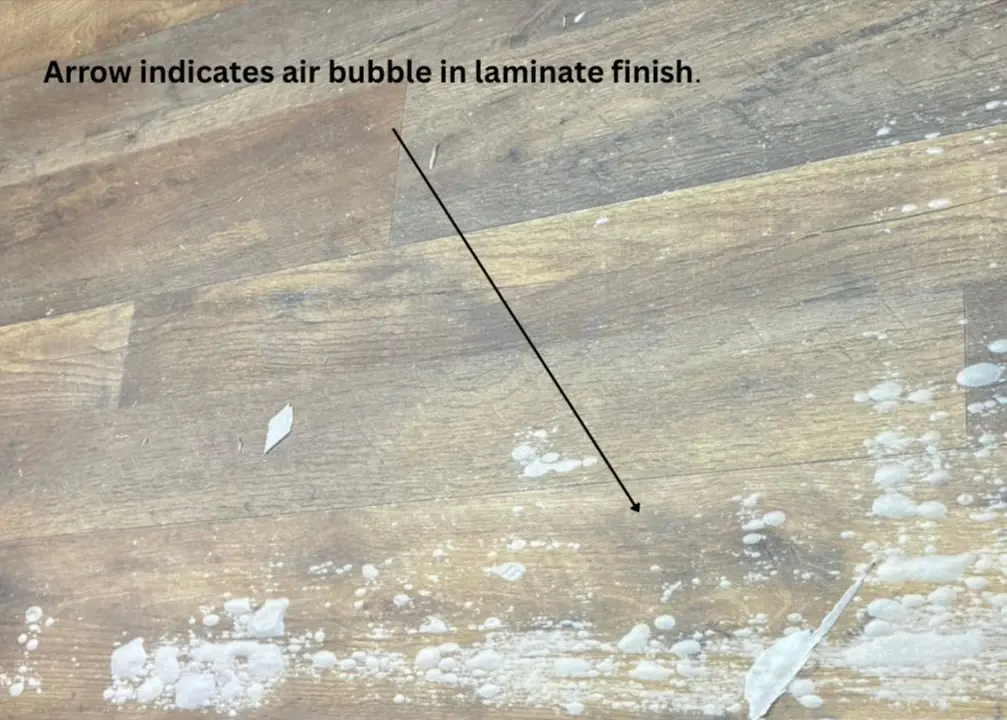

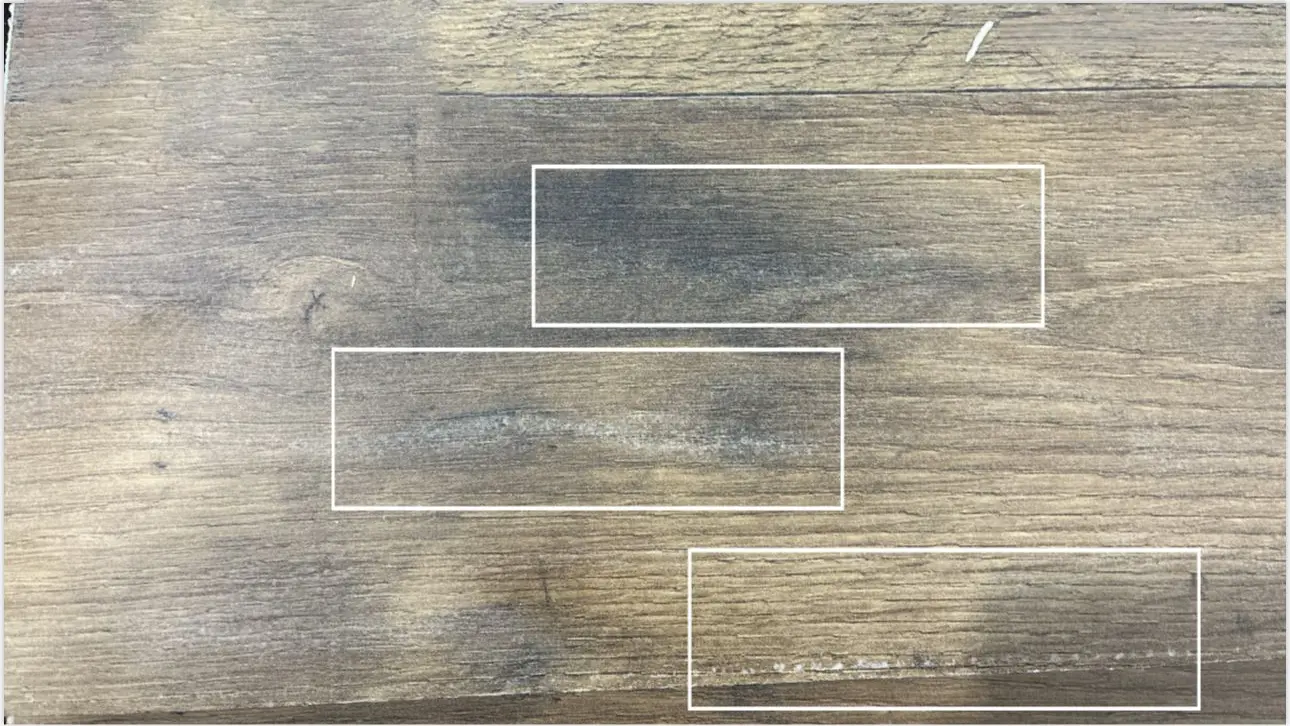

• Surface contamination that reduces performance in coatings and flooring applications

• Warping, blistering, or delamination in urea overlay and decorative papers

• Inconsistent production leading to higher reject rates and increased costs

Our Approach

At WeïssGrit™, moisture control isn’t an afterthought — it’s engineered into every step of the supply chain. We combine protective packaging, global oversight, and materials expertise to safeguard your inputs from origin to final delivery.

• Advanced Packaging: Barrier liners, desiccants, and custom wrapping systems designed for bulk bags, boxes, and rolls.

• Process Oversight: Independent quality checks at factories, warehouses, and shipping points to ensure procedures are followed.

• Owner’s Rep Services: Through Weïss Advanced Manufacturing, we act as your third-party global representative, managing moisture control protocols across multiple suppliers and regions.

• Integrated Solutions: Aluminum oxide, urea overlay paper, and decorative paper shipped together with protective packaging for consistent results.

Results You Can Measure

By combining high-performance materials with strict moisture-control protocols, WeïssGrit™ helps customers:

• Reduce rejects and rework

• Maintain consistent performance across production runs

• Lower total costs by preventing damage at the source

• Protect shipments across long distances and multiple climates

Partner With Confidence

Moisture damage is preventable — and WeïssGrit™ provides the systems, products, and oversight to ensure your supply chain stays protected.

Contact us